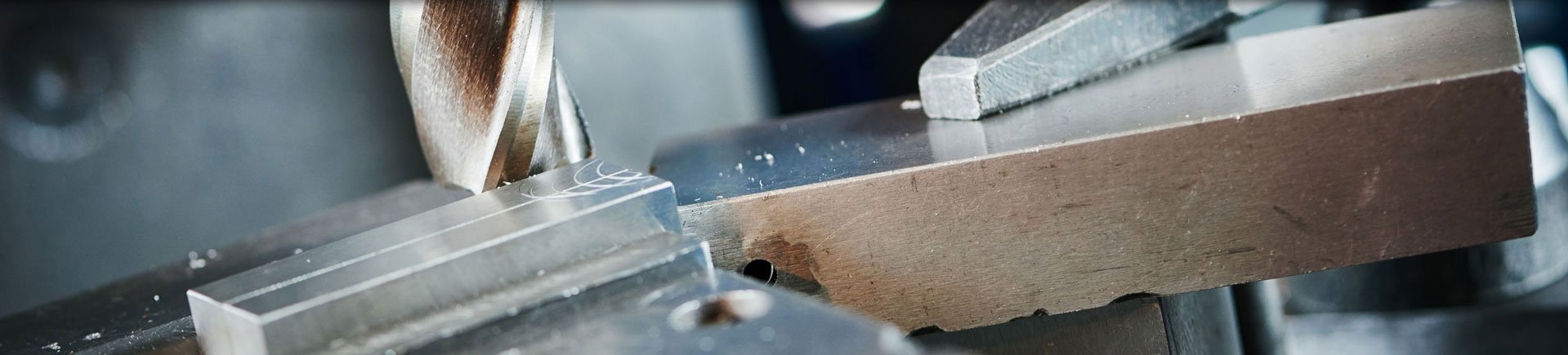

Vertical Machining Center (Half Closed Loop)-XH716C

CNC

X, Y, Z 3-axis servo direct connects control half closed loop of vertical machining center, three axis are rectangular quenching hardened rail, rail wide, big span. Spindle is driven by servo motor through the synchronous belt.Can be achieved a variety of complex parts such like disc, plate, shell, CAM, mold, can complete drilling, milling, boring, expanding and reaming, rigidity tapping and other process, suitable for workpieces of many varieties, medium and small batch production, can meet for parts processing of complex, high precision.Can match the fourth axis of rotation.