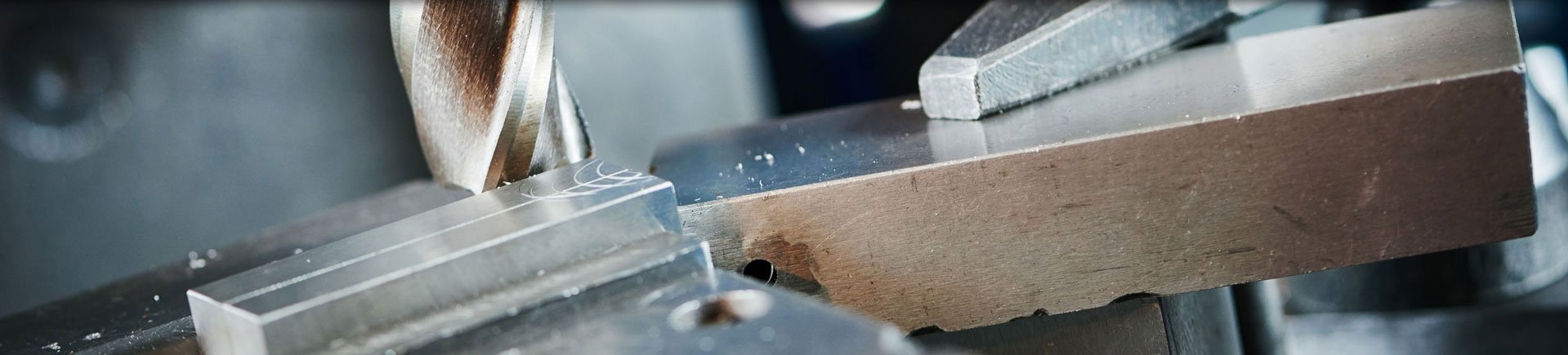

CLK6140S CNC Lathe (slant bed)

CNC

This machine is a fully functional slant bed CNC lathes, especially suitable for small and medium-sized plate, short shaft parts of high speed, high precision machining. There are two straight axis X, Z, can do long stroke integral movement by hydraulic driven tailstock . be able to complete functions once clamping: turning, drilling, boring, tapping, reaming, and others.